this is a pretty long one so if understanding more about putter or what makes a great putt is not your cup of tea, stay clear.

Face Balance and Sweet SpotBefore I got into this putter development project, there were some areas that I did not know about.

I will start with a least known and understood area - by adjusting the lie of a putter we will alter the face balance and shift the sweet spot of the putter. I bet SC knew but did nothing about it.

Putter WeightIn the putter market today, manufacturers are offering different weighted putter head to suit demands. Often the solution is making adding weight at the sole or flange so that the total weight is achieved. This also help to lower cost by having just 1 putter head and different weight ports to achieve a range of weights from 340 to 360g as in the case of Scotty Camerons. However what they have not disclosed is when a putter is bent more than ½ degree, there is an obvious change to the Face Balance and the Sweet Spot of the putter.

For most golfers they will not be able to tell the difference but in the hands of a highly sensitive player, there is quite a change.

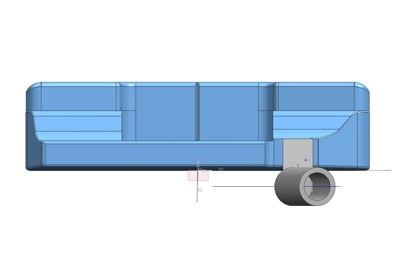

I have attached a couple of diagrams to show you what I mean.

heres another look from the top...

If we use the same head and bend the lie by one to two degrees, you can see that there is an effect on the sweet spot as well as the face balance of the putter. The software that was used to design this putter has the ability to calculate the FB to 1/1000 of a degree.

How do we design and built a constant FB putter?It starts from an accurate putter design using a proven state of the art software system. The designers are able to calculate everything from FB to sweet spot location and weight distribution. What followed next is milling each putter individually, from a solid block of SS 303, within a fixed tolerance and strict milling process. This tolerance includes the weight, the lie, the variable face loft, depth of RDE mill and MOI reading.

And to achieve what they did on the RDE face, it calls for a high-speed ultra-capable freeloading CNC milling machine. I did not know that a machine like this is aerospace graded and require a special permit from the US government to install. So it’s no surprise that Bettinardi who has the same CNC machine holds an advantage over many of its competitors including SC and TP mills.

The ZO Blade RDE putters is designed and developed in a facility with 34 General graded free loading milling machines and 2 Aerospace Grade CNC machines.

We are currently pursing the course to develop a 345 and a 355 putter, both in 69 and 71degrees lie. By doing so, we have to create 4 SKU (stock keeping unit) instead of just one head and different weights.

But why do we do it when it is easier to produce just one head with different weights and even changeable hosels.

So what is it that Zen is offering to their user?It is important that we constantly remind ourselves when we bring on new products that we need to think of effects and not features. So what’s the effect of the all the manufacturing technology behind this putter?

1. It allows us to meticulously and accurately create the RDE (Reduced Dimple Technology) on every putter face. The RDE is a proven patented technology that increases accuracy of every putt. (see footnote)

The effects are a more definite roll off the putter face, an exceptional pleasant and soft feel upon impact and accuracy on the intended line.2. When we minimize the need to alter the lie of the putter we ensure that the sweet spot stays constant to the original specifications. This eliminates the possibility of adverse club head rotation and reduces side-spin when the stroke is off centre.

3. When a putter orientation is off, it will affect inertia in the stroke, which in turn change stroke mechanics.

Effects for 2 and 3 are not something that many golfers can immediately relate to because until now, they have not tried the range of putters that offers the quality of the ball roll off the face, in both sweet and off hits. That’s probably the reason why those who have tried the Zen prototype want more than just trying them.4. Last but not least is the finesse of the product itself. I am a collector of all kinds of putters and if we compare the prototype Zen to the likes of the Tour Bettinardi and even the Circle T, I can say that besides the goodwill of the brand, we probably spent more creating this baby than what SC spent on producing the Circle T 009 or RJB on the Tour Bettinardis.

The Zen Oracle inventor and founder, Nick Middleton wanted to produce a putter that’s as accurate and precise as possible but more importantly, he wants to set Zen apart from the rest of the retail products immediately. His brief was to produce a Tour Specs customisable product but produced in a manner that the average golfer can get the opportunity to own and use one without burning a hole in the pocket.

I am very honoured to be involved in this project and I believe the extra effort in manufacturing process and investment in cost is worth it as exacting precision in each putter is instantly noticeable and felt when one takes the first stroke.

Footnote: The Zen Oracle Blade RDE is not available commercially until late or early next year. We are still in prototyping stage and this is not solicitation to procure orders.

What is RDE?RDE Technology counteracts the adverse effect of the golf ball dimples.

Scientific evaluation and development with players on the US & European Tours has proven that “dimple error” can cause perfect aligned putts to miss the hole from only five feet.

Zen RDE Series features the patented “Ready” RDE (Reduced Dimple Error) technology. Precisely designed micro ridges are milled into the putter face that minimize contact with the ball and improves impact dispersion of 50%. The results being that putts stay online, roll beautifully and have a feel that is both soft and responsive coming off of the face for maximum confidence and control.

all diagrams and photos are properties of Zen Oracle, UK and cannot be reproduced with prior approval.

Thank You.

DGman